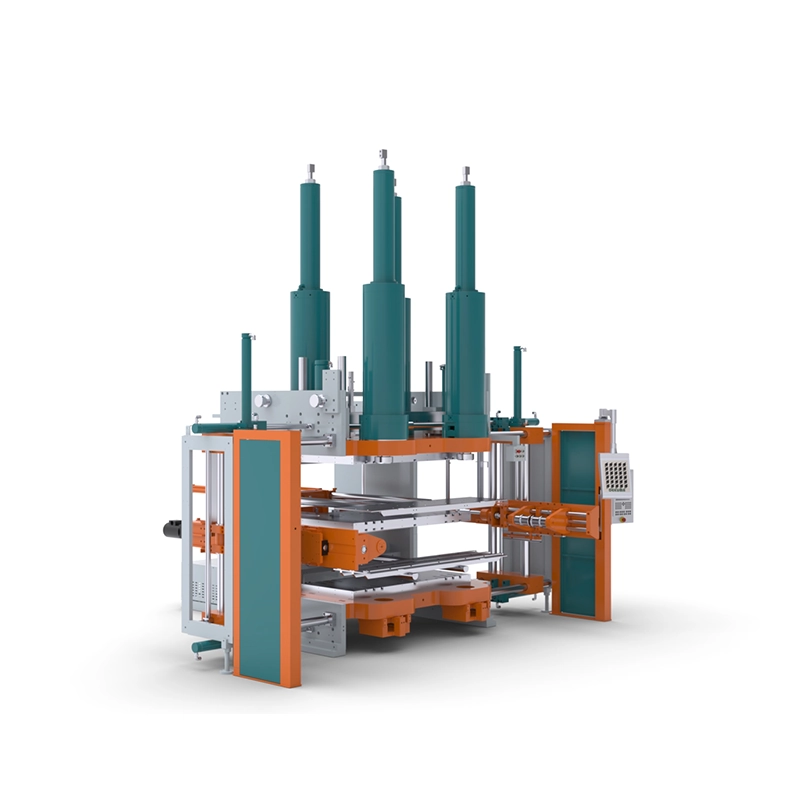

With regard to the rubber vulcanizing press machine, Dekuma considers it to be more than just a piece of machinery; rather, they consider it to be an essential component in a highly advanced production line. This approach influences the way in which we build solutions for specialized production, such as a production line that is solely dedicated to rubber track and tire manufacturing. Intelligent elements that answer modern operational needs, such as energy management and process control, are incorporated into our designs, which take our attention beyond simple functionality.

Engineered for Responsible Production

A significant feature of our rubber vulcanizing machine is its clever curing shutdown system. This innovation automatically halts the main motor during extended vulcanization cycles while the system maintains full lock-in pressure. This specific approach directly reduces overall power consumption. For a high-volume rubber track production line, this capability supports lower operating costs and a reduced environmental footprint without any sacrifice in the quality of the final product.

Integrated Systems for Informed Operation

Control and oversight are provided by a highly customized B&R system. This system offers precise management over the rubber vulcanizing press machine parameters and securely stores numerous production recipes. Furthermore, integration with the Dekuma iSee4.0 cloud platform allows for real-time monitoring of key metrics like energy use, temperature, and pressure. This connectivity provides valuable data for maintenance planning and enables remote oversight of the rubber vulcanizing machine status.

The method developed by Dekuma offers a significant competitive advantage in industries that are subdivided because it combines intelligent efficiency with durable vulcanization. With this combination of dependable pressure retention and data-driven oversight, it is possible to achieve constant production for difficult applications such as intricate rubber tracks and technical molded items.