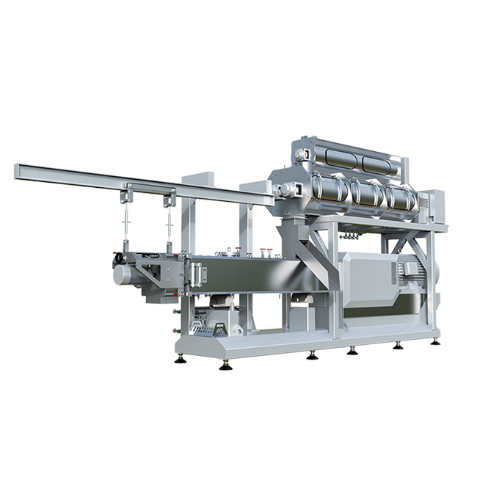

FAMSUN, a trusted global leader in food and feed processing technologies, presents the Twin-Screw Food Extruder, a solution that strikes the well-balanced between product taste and nutrition. By using advanced extrusion technology, FAMSUN empowers manufacturers to produce food products that are both flavorful and health-conscious.

Nutrient Retention Through Advanced Extrusion

The Twin-Screw Food Extruder utilizes controlled temperature, pressure, and moisture conditions to process ingredients in a way that preserves essential nutrients. This method reduces the loss of vitamins and minerals commonly found in conventional cooking methods. As a result, the finished products maintain their nutritional integrity, offering consumers healthier food choices without compromising on quality.

Improved Taste and Consumer Appeal

Thanks to FAMSUN’s innovative design, the extrusion process not only retains nutrition but also significantly enhances product taste. The twin screw extruder allows for precise control of cooking parameters, ensuring consistent texture, flavor development, and mouthfeel. These characteristics are critical in developing food products that are not only good for health but also highly attractive to consumers, increasing market competitiveness.

Conclusion:

The FAMSUN Twin-Screw Food Extruder is a powerful tool for producing nutritious and great-tasting food products. With its ability to maintain the value of raw materials while improving sensory appeal, this twin screw extruder offers food manufacturers a reliable solution to meet modern consumer demands. FAMSUN continues to lead the way in extrusion technology, ensuring food that’s as healthy as it is delicious.